Case Study: Didcot STW Inlet Pumping Station – Comprehensive Refurbishment

Summary

C&P Engineering Services Ltd successfully executed a major refurbishment at the Didcot Sewage Treatment Works, focusing on enhancing the Inlet Pumping Station. C&P Engineering Services undertook the role of Principal Contractor for the duration of the works, ensuring full compliance with the Construction (Design and Management) Regulations 2015 (CDM).

This involved the coordination of all on-site activities, the management of health and safety protocols, and the oversight of subcontractors to maintain regulatory standards and deliver the project safely and effectively. The project was undertaken to address critical infrastructural needs due to aging metalwork and water ingress into existing electrical enclosures. This case study details the challenges faced, strategies implemented, outcomes, and stakeholder feedback, highlighting the project’s impact on boosting operational efficiency, safety compliance and upgrading system reliability.

Project Details

- Client: Thames Water

- Location: Didcot STW, Basil Hill Road, Didcot, Oxfordshire, OX11 7HJ

- Project Scope: Replacement and upgrade of the handrailing, junction boxes, and electrical systems along the walkway of the Pumping Station.

- Project Duration: The project spanned approximately one month, from initiation on 25/02/25 to completion on 31/03/25.

- Project Manager: Jonathan Richards

Background

The Inlet Pumping Station at Didcot STW had experienced a progressive decline in performance standards due to a corrosive environment that led to material degradation and water ingress into existing electrical enclosures. These challenges necessitated a comprehensive refurbishment to enhance the operational integrity of the pumping station, which is crucial for the area’s wastewater management.

Objectives

- Enhance Safety Compliance: Address all health and safety hazards by replacing corroded metalwork and ensuring all electrical installations are up to the latest safety standards.

- Improve Operational Efficiency: Redesign the electrical layout to prevent water ingress and facilitate easier maintenance and pump operations.

- Ensure Long-term Durability: Use materials and designs that provide resistance to environmental and chemical exposures at the site.

Challenges

- Corrosion Damage: The existing stainless steel handrails and metal fixtures were extensively corroded due to exposure to H2S gas and other corrosive elements.

- Electrical: Upgrading the containment and local isolators/junction boxes whilst keeping the inlet fully operational throughout the project.

- Maintenance Access: The original positioning of electrical junction boxes and cabling obstructed routine maintenance activities.

Solutions

- Infrastructure Overhaul: All handrails were replaced with stainless steel to resist corrosion. Electrical junction boxes were upgraded to IP65 standard to ensure full water and dust protection.

- Redesign of Electrical Installations: The project involved a strategic relocation and redesign of electrical systems to enhance accessibility and functionality. This included repositioning junction boxes away from direct exposure to elements and adjusting cable routing to clear operational pathways.

- Enhanced Safety Measures: Installation of new local isolator marshalling boxes (LIMBs) and actuator LIMBs, along with comprehensive site-specific hazardous area compliance, ensured that all installations met the stringent DSEAR regulations.

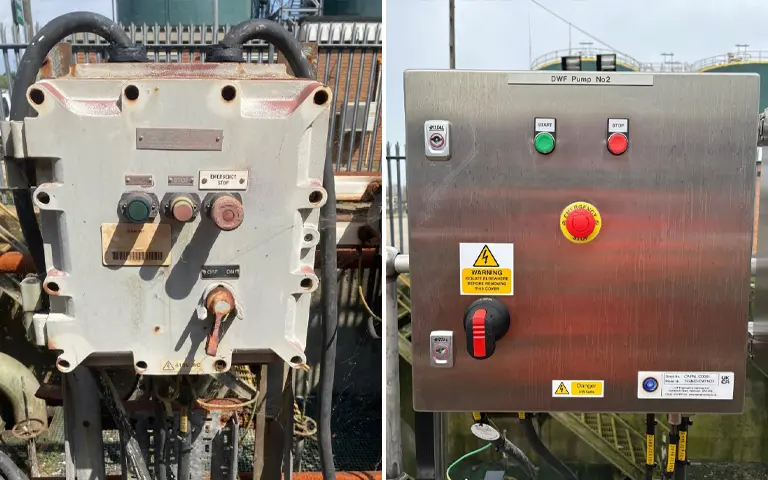

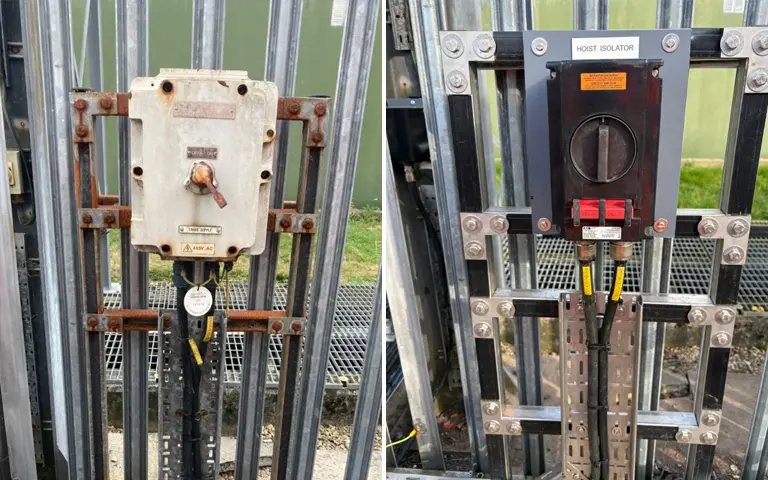

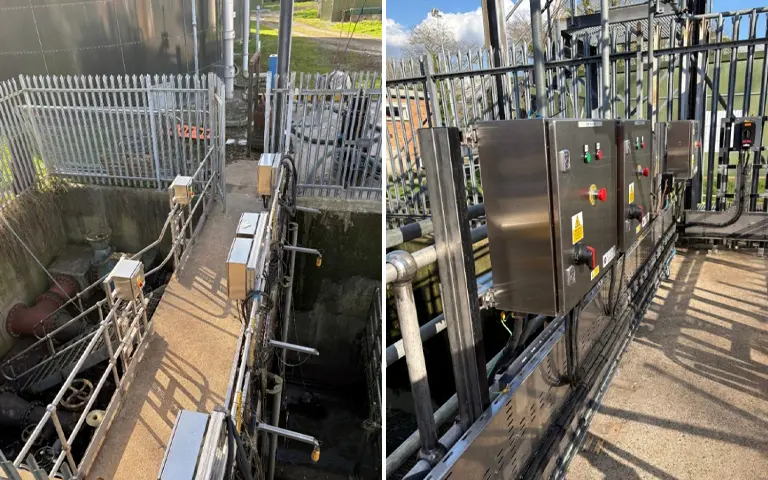

Before & After

Implementation

The project adhered to a meticulous schedule that accommodated the operational requirements of the Inlet Pumping Station, ensuring minimal downtime. The project management team, led by Jonathan Richards, maintained rigorous standards of communication and documentation, as outlined in the initial Scope of Work documentation.

Results and Impact

- Safety Enhancements: The project significantly mitigated the risk of accidents due to improved structural integrity and electrical safety, with new installations providing better resistance to environmental factors.

- Operational Improvements: The operational efficiency of the station was enhanced with better electrical reliability and accessibility, reducing maintenance time and pump downtime.

- Positive Feedback: The project received commendations for its execution standards and impact, particularly from operational staff who noted substantial improvements in safety and usability.

Pre-Existing Installation

After Completion

Conclusion

The Didcot STW – Inlet Pumping Station refurbishment project stands as a testament to C&P Engineering Services commitment to excellence in addressing critical infrastructure needs. Through strategic planning, technical expertise, and a focus on safety and operational continuity, the project has not only resolved issues but also enhanced the overall functionality and safety of the facility.

Related Resources:

- Learn more about our Hazardous Area Services.

- Explore C&P Training Services for your electrical and CompEx training requirements, gaining industry leading certification.

- Discover our Control Panel Services, including design, manufacturing, and installation tailored to your operational needs.

Contact us today:

- Phone: 01792 897 002

- Email: info@cpengineering.co.uk

Connect with us:

"I am thoroughly impressed with the diligence and quality of work C&P Engineering Services delivered on this project. It has set a benchmark for future projects in terms of both safety and operational efficacy. Jon Richards' leadership in project management was particularly commendable."

Henry Crompton, Lead Project Engineer, Thames Water